Hydrogen is the most abundant chemical element on our planet, it is present in 75% of matter. However, we never find it isolated, but in the company of other chemical elements such as oxygen forming water, or carbon forming organic compounds, such as hydrocarbons. Hydrogen is extremely light, storable and does not generate greenhouse gas emissions when used, making it a good candidate as a fuel. But it is not a primary energy source, but rather an energy vector, meaning that it is necessary to use various processes for its generation.

Looking to the near future and the almost mandatory decarbonization of the energy matrix that the main economies of the globe must face, electrification and the use of hydrogen technologies appear on the scene as the main actors in this energy transition that will take place at a global level, and that will transform society by changing the way we relate to the environment.

Hydrogen technologies represent a vanguard in the field of energy and sustainability, offering innovative solutions to address challenges related to energy production and consumption. Today we are in the early stages of development of several technologies associated with generation, transportation; uses and conversion of hydrogen, with a long way to go in research, development and innovation in this scientific field. At EnergyLab we actively work in all these stages, from the generation of scientific knowledge, its application and technological validation in real application environments. Without a doubt, hydrogen has become a key resource in the transition towards a cleaner and more sustainable energy future.

Hydrogen can be produced from a variety of sources, including water electrolysis using renewable energy, such as solar or wind, or through natural gas reforming processes with carbon capture and storage. The hydrogen generated can be used in a wide range of applications, from electric power generation, to transportation and manufacturing industries (steel, chemical, agricultural, glass, etc.). It is important to note that there are different types of hydrogen, classified according to their production method and their level of carbon emissions, and they are distinguished by color, which helps identify their origin and environmental impact. The main types of hydrogen are:

- Grey Hydrogen: This type of hydrogen is produced from natural gas through the steam reforming process, which involves carbon dioxide emissions. It is the most common production method today, but its prolonged use is not sustainable due to its contribution to climate change.

- Blue Hydrogen: Similar to gray hydrogen, blue hydrogen is produced from natural gas, but with the difference that carbon emissions are captured and stored, which significantly reduces its environmental impact. It is a more sustainable option compared to grey hydrogen.

- Green Hydrogen: Green hydrogen is produced through the electrolysis of water using renewable energy, such as solar or wind. It is considered the cleanest and most sustainable type of hydrogen, since it does not generate carbon emissions during its production. It is critical in the pursuit of a truly sustainable, low-carbon hydrogen economy.

These different colors of hydrogen reflect the commitment to reducing greenhouse gas emissions and the transition towards a cleaner economy, and green hydrogen will undoubtedly be the key energy vector to achieve the decarbonization of the planet and the objectives set for 2050 in the fight against climate change.

In addition to the different types of hydrogen, it is essential to understand the devices and technologies that allow its production, storage and efficient use. Among these devices, electrolyzers and fuel cells play a crucial role in the green hydrogen economy.

Electrolyzers are devices that use electrical energy to break down water into hydrogen and oxygen. The application of an electrical potential breaks the bonds between oxygen and hydrogen atoms, producing these elements in free form in a gaseous state. The applied electrical potential difference is what determines the efficiency of these devices. Among the most prominent types are:

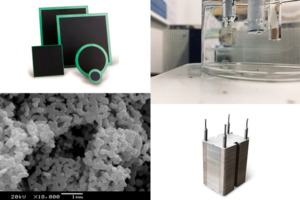

Proton Exchange Membrane (PEM) Electrolyzers

These electrolyzers use a proton exchange membrane to separate hydrogen and oxygen from water. They are known for their efficiency and rapid response capabilities, making them ideal for applications where dynamic hydrogen production is required, such as the transportation sector.

Anion Exchange Membrane Electrolyzers (AEM)

Similar to PEM electrolyzers, AEMs use an anion exchange membrane for gas separation. Although still under development, AEM electrolyzers show potential to reduce costs and improve durability compared to PEMs.

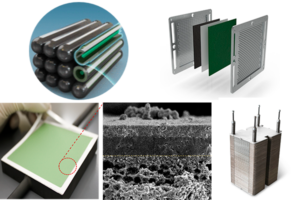

Solid Oxide Electrolyzers (SOEC)

These devices operate at high temperatures and use solid oxides as electrolytes to split water into hydrogen and oxygen. Despite their complexity and operating requirements, SOEC electrolyzers have the advantage of using waste heat and being compatible with high temperature energy sources, such as concentrated solar energy. It has been widely demonstrated that the efficiency of these devices is much higher than any of the conventional methods (AEM, PEM, etc.).

On the other hand, fuel cells (FC) are devices that convert the chemical energy of hydrogen into electricity and heat efficiently and cleanly. There are two main types of fuel cells, which are:

Solid Oxide Fuel Cells (SOFC)

These fuel cells use solid oxides as electrolytes and operate at elevated temperatures. They are highly efficient and suitable for stationary applications, such as distributed power generation and cogeneration systems.

Proton Exchange Membrane Fuel Cells (PEMFC)

PEMFC fuel cells use a proton exchange membrane as the electrolyte and operate at lower temperatures than SOFCs. They are ideal for mobile and portable applications such as hydrogen vehicles, due to their fast response and high power density.

These devices and technologies represent the foundation of hydrogen infrastructure, enabling its efficient production, storage and utilization in a variety of industrial, commercial and residential applications. Its continuous evolution and development are essential to move towards a more sustainable and decarbonized energy future.

At EnergyLab we investigate these green hydrogen production and storage technologies with the aim of developing efficient and sustainable methodologies that allow this knowledge to be transferred to the business community and industry, thus improving the generation and conversion processes of clean, accessible and low-cost energy.

The transition to an economy based on hydrogen generates important technical, regulatory, economic and market development challenges, and although there is currently not sufficient production of green hydrogen due to its high equipment cost, the situation is already changing. thanks to the cheaper renewable energies in recent years. In this context, governments and institutions are beginning to commit to the 2050 objectives, and the European Union already identifies green hydrogen as a key fuel in this period of decarbonization, with the development of its production technologies being a priority.