EnergyLab offices and laboratories are located at the CITEXVI Building (Vigo Technological City). These facilities are completely destined to offer advanced technological services to develop business R&D, promoting its location, the generation of synergies linked to cooperation among technology centres, university research groups, technology-based companies as well as industrial and business network in order to improve business competitiveness and technological excellence.

EnergyLab laboratories include high-tech equipment and offer their services to develop R&D projects related to the recovery of organic and biomass waste together with new biofuels testing for transport.

Our centre owns the scientific and technological equipment to characterise both the starting residues (substrates) and the products of anaerobic digestion (biogas and digestate) and those of the dark fermentation process (biohydrogen). In addition, it has a space dedicated to studying the technical and economic feasibility of novel methods for cleaning and purifying renewable gases or nutrient recovery on a laboratory scale. Among them, it must be underlined:

This laboratory accomplishes analysis like chemical oxygen demand, pH and conductivity, total nitrogen and ammonium, humidity, total solids, volatile solids, total suspended solids, volatile suspended solids, alkalinity ratio, short-chain fatty acids, anions (nitrite, nitrate, sulfate, phosphate) and the determination of biogas composition by gas chromatography.

It is also possible to carry out experiments in “batch” reactors and semi-continuous reactors in which the maximum potential for biogas and/or biohydrogen generation is determined, as well as the presence of inhibitory compounds in the residue.

EnergyLab has a laboratory of characterisation and valuation of biomass through agroforestry and residual sources, that contains specific equipment for the characterisation of biomass, more specifically for the performance of an immediate analysis (determination of humidity, ash content, volatile matter and fixed carbon) and determination of calorific value by an isoperibol bomb calorimeter.

In addition, we have an innovative system for energy recovery from biomass, a micro-cogeneration bank with ORC, based on a multi-fuel biomass boiler that feeds a low-power Organic Rankine Cycle, thus allowing the simultaneous production of heat and electricity on a small scale through the use of low-temperature thermal energy (up to 100°C). The system described is fully sensorized and is equipped with a SCADA system based on Labview that allows monitoring and control of the process in real time, being able to obtain a complete technical characterization of the SILO- -BOILER- CHIMNEY-ORC system. The gaseous and particulate emissions produced in the process are measured by separate gas and particulate analyzers.

On the other hand, we have a gasification plant that consists of an allothermic fluidized bed reactor with an approximate feeding capacity of 0.5 kg/h. The plant is designed to process WWTP sludge with a moisture level of no more than 25%, but its design and equipment allow it to operate with other types of waste (lignocellulosic biomass, etc.). In addition to the gasifier, the plant has systems for feeding biomass and carbonating agents and an area for treatment and adjustment of the composition of the synthesis gas produced, consisting mainly of a cyclone, a tar removal system and a bed reactor fixed catalytic designed for the hydrogen enrichment of the exhaust gas. The composition of the off-gas is continuously monitored by a microchromatograph.

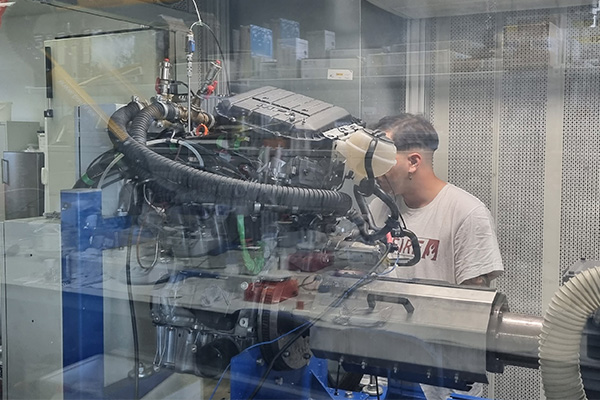

EnergyLab has specialised equipment that allows the centre to investigate alternative fuels. The centre has an engine test bench for new gaseous fuels, equipped with a dualised diesel cycle engine and an Otto cycle engine with bifuel capacities, fully sensorised and with regenerative braking and emission measurement systems (CO2, CO, NOx…)

In relation to fuel gases, this unit has a gas mixer that allows obtaining a gas stream with different proportions of the second gas, and a system equipped with sensors to determine the permeability of different pipe materials to gas streams rich in H2.

It also has a micro-cogeneration bank with ORC (Organic Rankine Cycle) for the generation of electricity from combustion gases.

EnergyLab is developing the line of research for the generation and conversion of hydrogen through electrochemical routes. The centre has laboratory-scale synthesis capacity and structural and electrochemical characterization techniques for ion exchange membranes and catalysts for electrolyzers: alkaline, polymeric membrane, and intermediate-temperature solid-state ceramics.

To understand in depth aspects related to the development of high electrochemical performance materials, the centre has an IVIUM potentiostat that works in a wide range of frequencies (1mHz – 1 MHz) which allows polarization studies (LSV and CV), electrochemical impedance spectroscopy (EIS), current-potential (I-V) curves, among other measurements. Conventional electro-analytical instrumentation is available such as conductivity meters specially designed for ionic conductivity measurements of polymeric membranes.

Energylab has a bench for measuring gas permeability through tubes. It allows testing under controlled conditions the permeability to gases (pure hydrogen, methane, hydrogen-methane mixtures…) through pipes made of different materials. Data are obtained on the permeability of the material under certain pressure conditions and type of gas.